Vlink always keenly pays attention to, identifies and understands the customers' needs or expectations, which are usually implied or must be fulfilled. It is converted into technical specifications with precise planning and careful design, and each contract is implemented with integrity and commitment. Rigorous internal control standards to ensure high product quality. Through continuous improvement and continuous pursuit of excellence, we strive to provide customers with quality products and services.

Quality Policy

Quality priority, Honesty

Technological innovation, Continuous Improvement

Quality Inspection Ability

Vlink has perfect imported production equipment, high-precision testing equipment and reliability experiment equipment, and has comprehensive testing and analysis capabilities.

Production equipment: Furukawa splicing machine, OPTEK laser cutting machine, etc.

Testing equipment: Sumix 3D interferometer, Yanagishi Giken fiber measurement equipment, fiber micro-crack detector, etc.

Reliability inspection equipment: high and low temperature circulation box, tensile test platform, PCT test box, etc

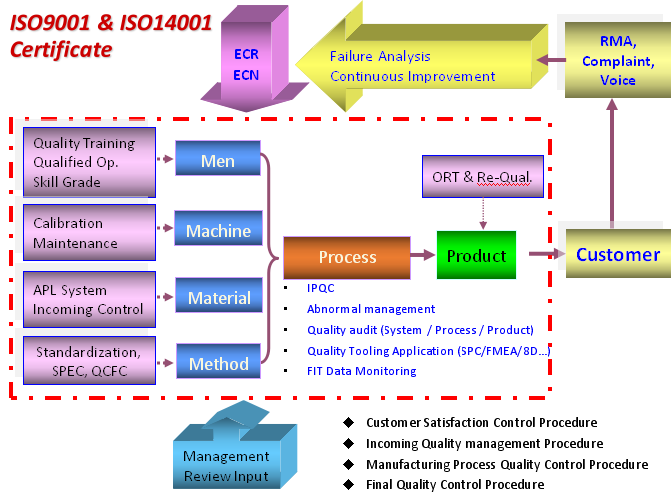

Quality Management System

From the supplier to the finished product, the quality management system runs through the entire process:

Incoming

Incoming materials shall be inspected strictly according to the incoming material operation process, incoming inspection operation instructions, product drawings, product retention samples, etc. to prevent the inflow of defective products.

Process

Through rigorous process control and IPQC inspections, quality control is performed on the first product and process inspection to reduce the occurrence of bad problems;

Shipping

Carry out OQC shipment inspection (C = 0 Sampling Plan) according to OQC operation specifications and finished product inspection standards to prevent outflow of defective products.

Exception handling and continuous improvement

Incoming materials NG: SCAR is adopted to follow up the implementation of the material improvement plan and confirm the improvement effect;

Process materials NG: Seven major methods of QC are used for statistical analysis, the improvement of the responsible department is tracked, and the implementation of the improvement measures is followed;

The customer complained about the defective product: the brainstorming method, 5 why and QC seven tools were used to analyze the cause, and corrective and preventive measures were determined. Follow-up effect verification was made. Permanent measures were formulated and standardized according to the effectiveness of the verification measures to prevent the same problems Happen once again. For the key performance indicators, SPC control charts are used to monitor the stability of the process and find opportunities for improvement.

Continuously carry out quality culture training activities

Strengthen the education and training of comprehensive quality management among employees and establish the idea of quality first. From the company's leadership and management to production line employees, all of them have strengthened the quality awareness, improved the quality level, and promoted the healthy and orderly development of company operations.

Establish a strict quality responsibility system, implement an excellent and effective management model for rewards and penalties, ensure the true implementation and implementation of quality strategies, and implement the implementation of quality details into every material, every person, and every work detail.

Continue to implement IPQC inspection, employee self-inspection, mutual inspection of teams, final inspection of finished products and other methods to ensure that products meet customer quality requirements. Actively carry out QCC quality activities and continuously improve quality. Summary of quality problems and improvements by week / month / year, hold special conferences on the improvement of process and quality problems, brainstorm ideas, verify implementation, and promote healthy development of quality improvement.